Solution of Impact Crusher Plugging

author:dahua time:2019-11-18

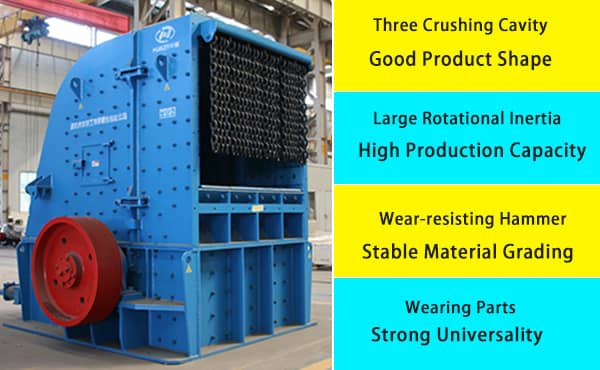

Impact crusher is used for the medium and fine crushing of medium hard rocks. Due to its high crushing force, simple structure, and strong universality of wearing parts, impact crusher is widely applied in the field of mining, metallurgy, water conservancy and hydropower, highway construction and other fields. During working process, the common problem is material plugging, how to solve this problem? Today, we will talk about the solution of impact crusher plugging.

1. Material humidity is high, easy to cause material plugging.

If the material contents too much water, and the viscosity is large, the material after processing is easy to adhere to the sieve hole and liner plate, that reducing the space of the crushing chamber, lower the passing rate and result material plugging.

Solution: Preheat treatment can be conduct at the front of impacting plate and feeding opening. Adding drying equipment, or expose to the sun to reduce the water content.

2. Material is too hard, too much or too large.

If the material is too hard, difficult to be processed, and the feeding size excesses the limit, the material would also plug the discharging opening.

Solution: Before the material enters the crushing chamber, it is necessary to make clear the applicable material for the crushing, especially the requirements on the nature of the material, so as to ensure the correct feeding of the crusher.

It is not easy to put too much material into the crushing chamber. Therefore, an electric bell and alarm flashing light can be installed in the feed opening to control the feeding, so as to avoid the clogging caused by too much material.

After the crushing of large material, it is put into the crushing chamber to make the material meet or close to the crushing requirements as far as possible, so as to avoid the clogging of the material

3. Fast feeding, slow discharging.

Normally, the feeding speed is the same as the discharging speed. If the former speed is too fast (equipment overload work) or the latter is too slow, it will lead to material plugging and the cannot operate normally.

Solution: To avoid overload of the machine, the feeding speed should be adjusted according to the processing capacity of the machine.

In the production, the size of the discharge port should be adjusted timely according to the actual situation so that the crushed material can be discharged smoothly. If the broken material changes, the size of the discharge opening should be adjusted accordingly.

4. The v-belt is loose and lacks the transmission kinetic energy.

The crusher relies on the triangle belt to transfer power to the groove wheel to achieve the purpose of material crushing. If the triangle belt is too loose, it cannot drive the groove wheel to affect the crushing of materials, or the broken materials cannot be discharged smoothly, causing blockage.

Solution: in the production of crushing process, pay attention to check the tightness of the triangle belt, if there is any improper, timely adjustment.

5. Wearing parts worn.

If the impact crusher wearing parts are worn, the poor crushing effect would also making material plugging.

Solution: Pay attention to the wearing parts abrasion, and timely replace the wearing parts to make sure the crushing effect and reduce material plugging.

6. The spindle of the equipment was damaged.

The spindle is the "lifeblood" of the normal operation of each part of the crusher. If the spindle is damaged, each part of the equipment will be "implicated" and cannot operate normally, thus making the equipment stop moving and causing material blockage.

Solution: Operation maintenance personnel should pay more attention to the maintenance of the spindle and lubrication timely, do a good job of maintenance, problems in a timely manner to solve, avoid affecting the normal production.

7. Improper operation.

Part of the reasons caused by blocking is the fault of the operator, which may be unfamiliar with the process or a temporary error caused by blocking.

Solution: Equipment operators should go through strict training, after qualified, should not only familiar with the operation of the equipment specification, but also know the whole process of production line, for example, before using, in strict accordance with the specifications to start the machine, to check whether the triangle is loose, avoid jam caused by improper operation material.

8. Improper design of crushing chamber.

The crushing chamber is the main "place" for material crushing and processing. After completion, it is discharged from the lower part. If the design is not proper, the material is easy to cause clogging in the lower part of the crushing chamber.

Solution: The crushing cavity can be improved by adopting a curved type of crushing cavity, that is, the angle of crushing cavity gradually decreases from top to bottom. This kind of crushing cavity is conducive to the downward fall of the broken bulk material, and also enables the small material to be discharged freely from the crushing zone, so that the material can be discharged smoothly and the blockage of the material can be reduced. In order to avoid all kinds of problems caused by improper equipment design, it is better for users to choose machines from large manufacturers.

Above is 8 solutions for impact crusher plugging, if you want to know more information about crusher supplier or crusher price, please contact us: lydhchina@huazn.com.

Previous Article:Safety Regulation of Jaw Crusher

Next Article: What types of Cone Crusher can Produce 200T/H?