How to improve the Working Efficiency of Jaw Crushers?

author:dahua time:2020-12-04

Jaw crusher plays a very important role in sand making production line. It can break large rocks into small pebbles with smaller grain size, which is convenient for subsequent sand making. Therefore, to improve the working efficiency of jaw crusher can enhance the production capacity of the whole production line.

How to improve the working efficiency of jaw crusher?

1. The size of the outlet is an intuitive factor that affects the working efficiency of jaw crusher. Therefore, in the production, it is necessary to adjust the size of the outlet reasonably according to the size requirements of the discharge particles. Only in this way can the jaw crusher really improve the production efficiency, so as to obtain high returns.

2. Control the feed size is one of the powerful measures to improve the output efficiency of jaw crusher. Generally speaking, the larger the feeding amount, the longer the crushing time of the jaw crusher, and the wear of the machine will also increase, which will cause a certain inhibition to the working efficiency of jaw crusher. Therefore, it is recommended that users must strictly control the feeding amount of materials in the production and operation process to minimize the damage to the jaw crusher.

3. Good maintenance is an important factor to ensure high production of jaw crusher. Any problems in maintenance will be reflected in the production of jaw crusher equipment, resulting in frequent failures, delayed production, consuming a large amount of equipment maintenance costs. Therefore, it is particularly important to do a good job in the crusher maintenance, which can not only reduce the wear and tear of accessories, extend the service life of jaw crusher, but also effectively improve work efficiency and reduce production costs.

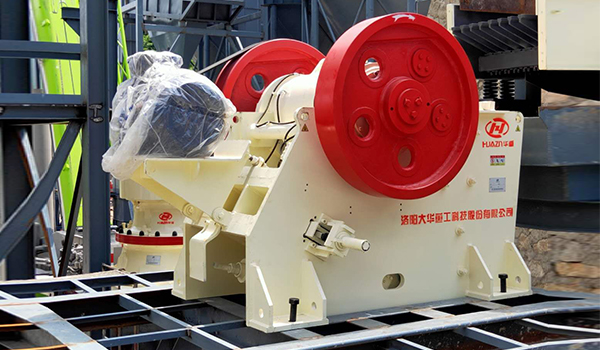

Luoyang Dahua, through 30 years of development, the company has formed a set of R & D, production, manufacturing, sales, and service in one. We are the supplier of crushing, grinding and screening equipment. Our quality control goes through the whole research and production processes to make sure that unqualified products will not leave factory. If you want to know more information, please contact our online service, or send email to lydhchina@huazn.com.

Previous Article:Is the Price of Crawler Type Mobile Crushing Station High?

Next Article: Crusher Machine Selection Factors