How to improve the Working Efficiency of Jaw Crusher?

author:dahua time:2019-10-30

Jaw crusher is the first crushing machine of sand and gravel crushing production line, so the efficiency of jaw crusher is directly related to the productivity of the whole production line. How to improve the working efficiency and reduce the failure rate of jaw crusher is very important. In terms of equipment operation and maintenance, operators should do a good job in the normal inspection; for operators, to strengthen the operator's equipment training, to help operators understand and master the operation skill. Below, we focus on the daily maintenance and operation that need to pay attention.

1. Preparation before starting the machine

1) check whether the main components are in good condition, whether the fastening bolts and other connecting parts are loose, and whether the safety device is complete;

2) check whether the feeding equipment, conveying equipment and electrical equipment are in good condition;

3) check whether the lubrication device is in good condition;

4) check whether the cooling water pipe valve is open;

5) check whether there is ore or sundries in the crushing chamber to ensure that the crusher starts without load.

2. Start and normal operation

1) when starting the main motor, please pay attention to the ammeter indication on the control cabinet. After 20-30s, the current will be reduced to the normal working current;

2) adjust and control the feeding to make the feeding evenly and the particle size of the material shall not exceed 80%-90% of the width of the feeding opening;

3) the sliding bearing temperature should not exceed 60, rolling bearing temperature should not exceed 70;

3. Stopping attentions

1) the sequence of stopping is opposite to that of driving, that is, following the direction of the production process;

2) the lubrication and cooling system can only be stopped after the crusher stops. The circulating cooling water in the bearing should be discharged in winter to avoid the bearing from freezing and cracking;

3) clean up and check all parts of the machine after shutdown.

4. Lubrication

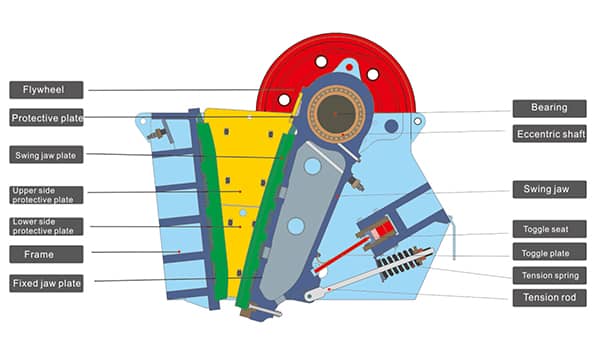

1) connecting rod bearing, eccentric shaft bearing and thrust plate elbow of jaw crusher shall be lubricated by lubrication oil. It is more suitable to use no.70 machine oil in summer and no.40 machine oil in winter. If the crusher is often continuous work, winter uses oil heating device, summer environment temperature is not too high, can be used no. 50 mechanical oil.

2) the oil temperature heater can preheat the lubrication oil before use in winter.

3) when the oil pump suddenly fails, the crusher needs 15-20 minutes to stop running due to the large pendulum power, then it is necessary to use hand pressure oil pump to feed oil, so that the bearing keeps lubrication and does not be burnt.

Luoyang Dahua, as a supplier of crushing machinery and grinding equipment, is committed to providing customers with crushing equipment with superior performance, good quality and stable operation. Production workshop covers an area of about 200,000 square meters, with advanced processing equipment, storage workshop clean and tidy, 5S standardized production management. If you want to know more about us, please contact: lydhchina@huazn.com.

Previous Article:What are the Complete Sets of Sand and Gravel Aggregate Production Lines?

Next Article: What Crushing Equipment is used for Pebble Sand Making?