Why should the Feeding Size of Sand Making Machine be strictly observed?

author:dahua time:2019-11-27

There are many types of sand making machine, different manufacturers have different naming methods. But the working principle of sand making machine is mostly similar, it has the function of crushing and shaping, and the main crushing way is "stone beat stone" and "stone beat iron". The stone crushing is realized by beating and kneading to meet different production requirements. Normally, we should observe the feeding requirement of sand making machine, otherwise, it will bring unnecessary trouble to our production.

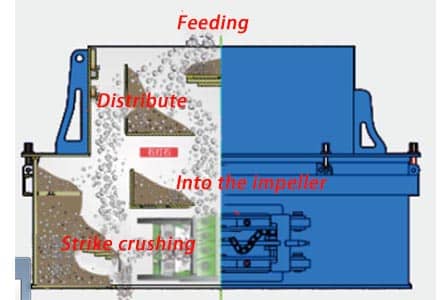

Working principle of sand making machine - The material is put into the sand making machine by the hopper and divided into two parts by the distributor. One part is put into the fast rolling impeller in the center of the distributor, which is rapidly promoted in the impeller, and its acceleration will be up to hundreds of times of gravity acceleration, and then it will be ejected from the three evenly distributed flow channels of the impeller at a speed of 60-70 meters per second. First, a part of the freely falling material around the distributor is crushed and broken, after that, they collided with the material liner inside the vortex support chamber, and were bounced by the material liner, which hit the head of the vortex chamber in an oblique upward direction, and then changed its motion direction, which was deflected and moved down, and the material emitted from the blade flow channel appeared continuous material curtain.

From the above working principle can be seen, the stone inside the sand machine will be emitted from the flow channel by the force of impeller. The projectile force of impeller is certain, if the stone is too large, the projectile strength is not enough. When the material falls freely around the distributor to strike, the strength is not enough to break the material to the specified size. If the material is too small, the projectile strength is too large, not enough to strike free falling material around the distributor, let alone break it to the required size.

Luoyang Dahua PLS series sand making machine has PLS550, PLS850II, PLS1200II and other 5 different models, the maximum feeding particle size is 30-60mm, the processing capacity is 24-715t/h. If the material to be crushed is larger than the maximum feeding size of sand making machine, also need to be crushed firstly, usually choose impact crusher or cone crusher. For specific selection of crushing equipment, please consult Luoyang Dahua online customer service or send email to lydhchina@huazn.com. Our sales engineer will recommend appropriate equipment for you according to your actual situation.

Previous Article:How to effectively reduce the Dust Pollution of Jaw Crusher?

Next Article: Crushing and Feeding Method of Vertical Impact Crusher