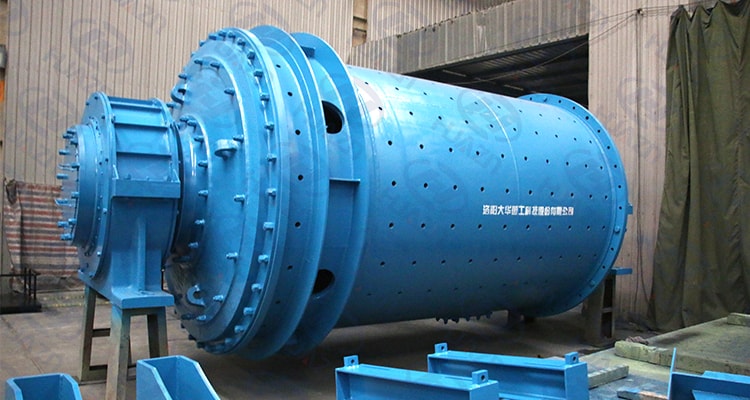

Ball Mill Troubleshooting

author:dahua time:2020-04-15

1. When the ball mill is running, there is a regular knocking sound, and the sound is very loud. This is part of the liner bolts are not tightened, when the ball mill rotation, liner hit the ball mill grinding barrel. Judge the part of ball mill liner according to the sound, find out the loose bolt and tighten it separately.

2. The temperature of ball mill and motor bearing increases, exceeding the regulations. With the hand test bearings are locally or wholly overheated, check and handle the ball mill from the following.

1) Lubrication point, whether the brand of lubricating oil used is consistent with the factory manual of the equipment.

2) Blockage, or the lubricating oil does not directly enter the lubrication point, the insufficient amount of oil causes overheating.

3) 1/3 ~ 1/2 of the void is more appropriate.

3. Ball mill reducer bearing heating:

In addition to take the inspection of ball mill bearing temperature rise, we should check whether the reducer vent is blocked, to dredge the vent.

4. After the ball mill motor starts with the reducer, it vibrates. The main reason is that the bearing outer ring is active.

Treatment: adjust the clearance according to the regulation to make the two shafts concentric. The coupling bolt is fastened symmetrically with the same torque. When the rotor is unbalanced, pull out the ball mill rotor for static balance.

5. Huge vibration occurs when the ball mill reducer drives the mill:

When the liner is installed on the mill, there is no secondary grouting, or the anchor bolt after the secondary grouting is not well fastened, the roller body is rotated by the hoist, causing the displacement of one end of the roller body, and the two axes are not on the straight line, so that the reducer drives the mill and produces vibration.

Treatment: to readjust the ball mill axis and reducer axis in the same plane axis line. Large ball mill has large volume, heavy weight, causing the foundation to subside, and displacement occurred. Set up monitoring settlement point beside the foundation, and make an observation and adjust when there is subsidence.

6. Abnormal operating sound of ball mill reducer:

The sound of ball mill reducer normally should be even and steady. If the gear produces a slight tapping sound, hoarse friction sound, there is no obvious change in the operation, you can continue to observe, to find out the reason. If the sound becomes louder and louder, stop the ball mill immediately for inspection.

Luoyang Dahua has rich experience in manufacturing stone ball mill machine, if you need any help during operation or purchase process, please contact us: lydhchina@huazn.com.

Previous Article:Why Mobile Stone Crusher is so Popular in Mining Industry?

Next Article: Ball Mill Machine Application